Products

-

CH-924 Servo Free Pressure Feeding 5 color printer slotter die cutter machine(Vacuum Transfer)

① Servo Free Pressure Feeding, simple operation and high accuracy。

② Leading edge paper feeding, increasing fan flow, making high-speed and low-speed paper feeding more accurate。

-

Four link slotting and Corner Cutter

Suitable for single, double and multiple corrugated carton production.

Compact structure, convenient use and maintenance. Transmission part adopt sprinkle lubricating system, ensure the machine precise and use life.

-

Blade electric adjusted type thin blade slitter scorer

Electric adjusted the apace of slitter blade, auto pneumatic locking, easy to operate, improve the efficiency.

Double guide optical axis, stable operation; inlay PU ring sela, clean and dust-proof.

Slitter part: adopt high quality tungsten steel blade, sharp and long work-life, slice more tidy, non-pressing and non-burr.

Scorer part:adopt 5 points scoring, scoring distance in-phase adjust, blazonry and easy to bend the carton sheet.

Adopt 8 shafts design, two shafts in front and back of the slitter, can minimize the length of paperboard machining.

Grinding part: adopt automatic and manual two kinds pneumatic grinding type, it could be grinding when working, improve work efficiency.

Adopt China famous brand or imported electric element, dependable performance. -

Computer Type Corrugated Carton Box Making Machine

Man-machine interface—PLC control, this system is the robot operating system. More humane, simple structure and easy to maintain. 1.Manual/auto feeder is available 2.Pre pressing roller,slitting blade and scorer holder are auto adjusted 3.Grinding knife is auto/manual 4.Cardboard thickness and press power are auto adjusted(Optional) 5.Jog for fine-adjusted 6.User-defined to set the distance of blades and scorers 7.Auto counter 8.Slitting and press line precision ±0.5mm

-

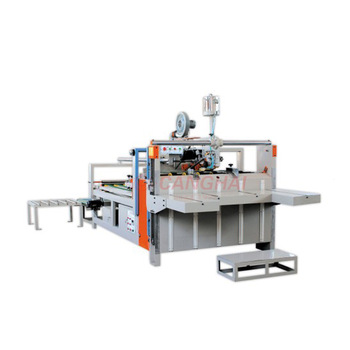

Semi-auto stitching machine

1. Mitsubishi double servo drive, accurate accuracy, reduced mechanical transmission parts, can effectively reduce the mechanical failure rate.

2. Weilun touch screen operation, parameters (nail distance, number of nails, nail type, back panel) change quickly and easily

3. The entire control system uses the Japanese Omron PLC control system.

4. The rear electric baffle is driven by a stepping motor, and the size is accurate, and the size is more convenient and quick.

-

Carton Box Stapler Stitching Machine

Our factory is a professional one producing DXJ stitch. The DXJ machine is designed according to the advantaged of the same kind of products produced at

home and abroad. The machine head is structured by double eccentric gears to work together: the pressure angle adopts installation style which is fit for wire cut and which is exchangeable.

-

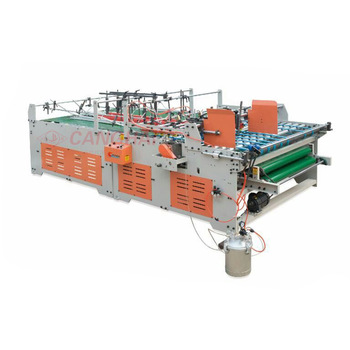

Two Pieces Corrugated Cardboard Gluer Machine

1.The feeding unit of the machine has two paper board stack to hold AB two pieces of papers, which helps to improve the production efficiency. Below adopt the air sucking structure, which is conducive to improve transport efficiency and accuracy.

2.Connecting unit adopts hot melt adhesive, four side gauge positioning, ensuring accurate register and high precision.

3.Folding unit adopts manual fold, which resolve the problem of hard to confirm fold place. The overlap margin can be controlled effectively.

4.The machine can be operated by two person. One stacks papers and collect finished job.The other fold the papers and feed them into compressing belt. The whole machine is of easy operation .

-

ZXJ-B Semi-Automatic Gluer

ZXJ-B type semi-automatic sticky box machine is in recent years the carton manufacturing of new environmental protection equipment, mainly for the carton adhesion, discard the traditional copper nail binding method, improve the production efficiency, ChanPinXing good quality.

Main frame: frame, lift workstation, conveying equipment, middle recently conveying equipment, pressure and device, finished product middle side output equipment, electrical control equipment.

-

Semi-automatic folder gluer machine

RS pressing type glue machine is developed for customer’ need, occupies little space Easy to operate without skill: the machine is good at producing small order, and changing the order. Widely be used: common box, abnormal color box which is one piece board to a box, if the machine be add auto spraying glue device, the machine also can glue Hook bottom box and four corner box Saving material:the material only be 1/3 of manual gluing. Saving workers: the max machine speed is 56m/min, 3-4times of manual gluing Firm gluing, tidy without spilling material: the double grinding gear can grind connect point to clear UV film or other plastic to enhance the glue material power, and solving

-

Lock Buttom Type Carton Box Making Machine

Semi-automatic folder gluer with locking bottom is mainly used for packaging, decorating industry, Folding of cartons.The machine to sticks, sticky side mainly,From the paper feeding, folding, paste glue, artificial homing to press box molding, to achieve the advantages of automation and manual operation complement each other

-

Automatic Folder Gluer Machine

Automatic Folder Gluer mainly used for color box packaging enterprises cartons, boxes bonding process. This is because the vast majority of domestic enterprises in the complex special packaging and corrugated carton boxes paste synthetic processes are used purely manual, which led to paste box molding processes across in enterprise, particularly in the corrugated box manufacturing enterprises employing the most, covering most, the minimum efficiency.

-

semi automatic type

(1) Adopt nodular cast iron-QT500-7, the mainframe wallboard casting by special technology process, thus featuring by high strength, never deformation and ensure the safety of the mainframe wallboard.

(2) Adopt Taiwan-imported intermittent mechanism to ensure that the machine operates accurately and reduce the occurrence of failure rate.