Welcome to our websites!

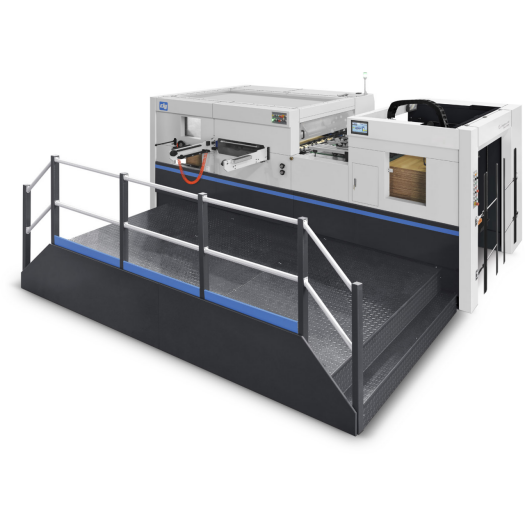

Chinese Professional Cardboard Paper Making Machine - 3 Ply Corrugated Cardboard Production Line – Canghai

Chinese Professional Cardboard Paper Making Machine - 3 Ply Corrugated Cardboard Production Line – Canghai Detail:

SPECIFICATION

|

No. |

Name |

Qty |

Feature |

|

1 |

RS Electrical Mill Roll Stand ( with trolley and track) |

3 |

–Toothed chuck,manual discbrakes,pneumatic mechanically actuated lift,panning left and right on the middle–Guide rail length is 4500 mm, the trolley adopt 10 mm plate welding |

|

2 |

PH-60 Pre-heater |

2 |

–The roller φ600 mm,Electric adjustment angle,adjusting heating area within the range of 360 ° |

|

3 |

SF-A12 Single Facer |

1 |

–Corrugated rollerφ320mm, 48CrMo high quality alloy steel,Tungsten Carbide–Independent gearbox,universal joint drive structure–Cylinder control lifting

–Pneumatic control glue,circulating supply glue –Man-machine display |

|

4 |

OB Conveying Bridge |

1 |

–The main beam is connected with the GB 200 channel steel,63 angle steel–Independent frequency motor drive paper conveying–Suction tension and electric correcting |

|

5 |

Triplex Pre-heater |

1 |

–The rollerφ600 mm,electric adjustment angle angle,adjusting heating area within the range of 360 ° |

|

6 |

GM-15 Glue Machine |

1 |

–Glue roller φ269mm,carved 25 line pit type mesh–With preheater device–Independent frequency motor drive

–Circulating supply glue with PLC control –Man-machine interface display |

|

7 |

DF-60 Double Facer |

1 |

–Main frame is 360 mm GB channel steel–Hot plate 600 mm 10pics with plating chrome–4 M cooling section

–Adopt pressure bar lifting by pneumatic control –The upper belt correct automatically –Frequency motor drive |

|

8 |

SS-E Electric Blade Machine |

1 |

–Blade adopt tungsten alloy steel–Electric adjusting and correcting –Automatically grinding–5 blade 8 line |

|

9 |

NC-12 Cut-Off |

1 |

–Full AC servo control–Energy storage type braking–Helical knife structure

–Oil-immersed gear transmission –10.4-inch touch screen display |

|

10 |

LS Sheet Delivery Machine |

1 |

–Electrical adjust the size of cardboard–Cardboard transverse output controlled by pneumatic;–Max stacking height 200mm |

|

11 |

Glue Making System |

1 |

–Customers supply the pipeline–The glue making device includes: carrier tank,main body tank,storage tank,glue feeding pump and returning pump |

|

12 |

Internal Steam System |

1 |

–Steam system components adopt GB valve: Contains rotary joint,up and down distributor ,drain valve and pressure gauge, etc–Boiler and pipeline supply by customer |

Product detail pictures:

Related Product Guide:

With our loaded working experience and thoughtful products and services, we've got been acknowledged as a reputable supplier for most international buyers for Chinese Professional Cardboard Paper Making Machine - 3 Ply Corrugated Cardboard Production Line – Canghai , The product will supply to all over the world, such as: Sri Lanka, Lisbon, Zimbabwe, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, be sure to click the button to acquire additional nformation.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

Write your message here and send it to us