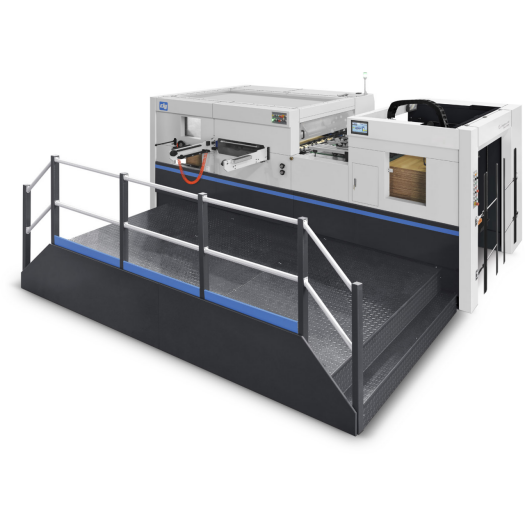

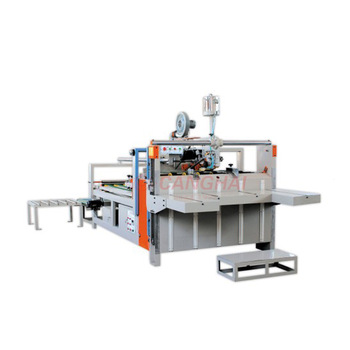

Factory Price For Creasing Cutting Machine - Automatic Printer Die Cutter Machine – Canghai

Factory Price For Creasing Cutting Machine - Automatic Printer Die Cutter Machine – Canghai Detail:

The main technical parameters

| No. | ||

| 1. | Design speed | 150piece/min |

| 2. | Working speed | 100-120pieces/min |

| 3. | Max feeding size | 1000*2100mm |

| 4. | Min feeding size | 300*650mm |

| 5. | Max printing area | 950*2000mm |

| 6. | Printing plate thickness | 7.2mm |

| 7. | Registration precision | ±0.5mm |

| 8. | Slotter precision | ±1.5mm |

| 9. | Max depth of slotting | 250mm |

Machine introduction

1. This machine is composed of paper feeding, printing, slotting or die cutting. It can complete the three-layer and five-layer corrugated board printing, slotting, die cutting and other processes at one time.

2. The thickness of the wallboard is 50mm, and the internal stress of medium frequency quenching and tempering increases the density, hardness, strength, toughness, and conduction performance of the wallboard, artificial aging treatment, large-scale machining center processing in pairs, high strength and high precision.

3. The transmission system adopts gear transmission, high-precision grinding technology, low noise, enhances the strength of the gear, and improves the transmission stability of the gear. All transmission gears are made of high-quality steel, quenched and tempered by high-frequency quenching, super-hard treatment, precision grinding, high strength and durable.

4. Bearings use famous brand bearings such as human, Harbin and Wafangdian, which are inspected one by one and qualified and put into storage.

5. Each unit is powered by a clutch and attached with an alarm bell. When the clutch is on and off, the alarm will continue to sound to ensure the safety of the operator. The clutch motor is equipped with a constant torque clutch, which can buffer the collision of each unit during wrong operation.

6. On-line master lock: the main motor is automatically protected when the equipment is not merged, and automatically stops when the operation signal is obtained.

7. The main motor starts with frequency conversion, and the motor adopts frequency conversion motor. Electrical appliances use famous brand products such as Siemens.

8. Pneumatic components: Pneumatic components adopt Yadeike and other famous brand products, and diaphragm pumps use Wuhan Jinchangjiang famous brand products.

9. The ink on the machine is even and the amount of ink can be controlled to prevent ink overflow and ensure that the exterior of the ink path is clean and sanitary.

10. The whole machine adopts closed spray lubrication to keep the gear highly lubricated. Each unit is equipped with a contact flow-type oil level balancing mechanism to prevent the lack or overflow of individual unit lubricants.

A.Paper feeding unit (independent front edge paper feed with double pull shaft)

1. An electric bell is attached to the clutch of the electric control machine, and a continuous bell alarm will be given during travel to ensure the safety of the operator.

2. The transmission shaft is equipped with a friction clutch to avoid malfunctions and damage to the machine.

3. The main motor starts with frequency conversion, and energy saving is increased by about 30%.

4 The main screen is a PLC color touch screen, which displays the phase setting of the printing and die cutting section, and can set and display the production quantity to the single alarm.

5. Adopting high-speed suction leading edge paper feeding system, the paper feeding is accurate and smooth.

6. Vacuum suction paper feeding, overcoming the different degree of bending of the cardboard, to ensure smooth paper feeding.

7. Electric adjustment of the side baffle, manual linkage adjustment of the front baffle clearance, and electric adjustment of the position of the rear baffle.

8. Alternate sheet feeding device (continuous or alternate sheet feeding can be selected as required).

9. The planned production quantity can be set. When the plan is completed, the system automatically instructs to stop the paper feed and issue a warning signal.

10. Equipped with high-quality brushes and a dust suction device, which can remove impurities on the printed surface of the cardboard and improve the printing quality.

11. The seamless steel tube on the paper feed roller is wrapped with wear-resistant rubber, and is balanced and corrected. The high-quality wear-resistant rubber improves the compressive strength of the cardboard and reduces damage to the corrugated cardboard.

12. The seamless steel tube of the lower paper feed roller is processed by the appearance embossing process, and the balance is corrected to improve the friction and ensure the accuracy of paper feed.

13.The gap between the paper feed rollers is adjusted quickly and manually, the adjustment range is 3-12mm, and the cross slider mechanism is adopted. During the adjustment, the transmission gear ensures the correct meshing state.

B.Printing unit

1. Printing roller

① The outer diameter of the printing roller (320mm).

②The material of the seamless steel tube of the printing roller is finely ground and hard chrome plated.

③Balance correction, stable operation.

④ Promise ratchet fixed rolling plate shaft, full hanging type groove hanging plate. It saves board hanging time and improves work efficiency.

⑤ Hanging board groove, suitable for 10mm hanging slats.

⑥ When loading and unloading the printing plate, the electric control of the foot switch is positive and negative.

⑦Phase adjustment: The printing roller is equipped with an automatic zero-reset device. The main screen PLC multi-function touch control is used. Click to enter the plate roller phase adjustment interface. It has functions such as zero return (optional).

2. Pressure roller

① High-quality seamless steel tube, made by deep hole boring machine, hardened and chrome plated on the outer circle.

②The stamping stick adopts high-frequency hot-packing and double-disk welding.

③ Balance correction, remove centrifugal force and run smoothly.

④The gap between the platen roller is adjusted quickly and manually, the adjustment range is 3-12mm, and it is connected by a cross slider. When adjusting, the transmission gear is engaged with the correct position.

3. Anilox roller (220 lines in one color and 240 lines in two colors)

①High-quality anilox roller, 200-300 lines / inch can be selected.

② The dots are consistent and the ink is evenly distributed.

③ The gap of the anilox roller is adjusted quickly and manually, the adjustment range is 1-8mm, and it is connected by a cross slider. When adjusting, the transmission gear ensures that the correct position is engaged.

④ Pneumatically lift the anilox roller to reduce the drying of ink in the anilox cavity when the printing plate is repeatedly inked and stopped for a short time.

4. Rubber roller

① The surface of the rubber roller steel roll is coated with excellent wear-resistant rubber, and the surface of the rubber roller is medium to high, which can compensate for the deformation of the force and improve the ink transfer effect.

② Equipped with automatic ink leveling device, which can realize the function of stopping ink without stopping.

5. Paper feeding upper and lower rollers

①The upper roller is equipped with two paper feed wheels. Seamless steel tube, deep hole boring of inner diameter, hard chrome of outer circle precision, high frequency hot fitting, double disc welding.

②The lower roller is seamless steel tube, boring with deep hole in inner diameter, hard chromium outer circle, high-frequency hot fitting, double-disc welding.

③ The gap between the paper feed rollers is adjusted quickly and manually, the adjustment range is 3-12mm, and the cross slider is used to connect. During the adjustment, the transmission gear ensures that the correct position is engaged.

6. Ink system

①Pneumatic diaphragm pump is used for ink supply, stable ink supply, simple operation and maintenance.

②Ink storage cup to prevent ink splash and exhaust.

③Stainless steel ink fountain, automatic cycle cleaning and inking.

Slotter

1.the slotter knife thickness 7mm, manufactured by high alloy , tooth profile cutting sharp , the abration resistance high

2.the slotter knife phasing crganization , the overtone structure , the frequency changer controls the brake , static 360 degree adjustment .

3.the slotter knife adjust by electric , the adjustment is quick and accurated.

4.regards the user to need to be possible to match the punch insiaiment

5.slotter deepartment canada supposes the prccop pression to roll around , sharpens the cardboard resistand to compression ability

6.the line ball cut the angle turn place addition compressing wheel disk , guaranteed the mouth paper box sticks the place to compress

Die cutter unit

①The crimping wheel axle is made of seamless steel tube, after two grinding processes, the surface is plated with hard chrome, and the movement is stable.

②The gap of the crimping wheel is adjusted quickly and manually, the adjustment range is 3-12mm, and it is connected by a cross slider. When adjusting, the transmission gear is engaged with the correct position.

③Rubber pad rubber pad rollers are processed and polished by seamless steel tubes with alloy structure and hard chrome plated.

④Uli rubber pads are made of Taiwan super-resistant, which can be used 6 million times under normal circumstances.

⑤The stencil roller and ULI rubber roller are automatically disengaged by the eccentric device when they are not in the moldless state, which can reduce the no-load load of the machine and prolong the life of ULI rubber and knife mold.

⑥Mechanical transmission Youli rubber roller moves 40 mm from side to side, and is equipped with a radial differential device, which can evenly distribute the rubber roller wear and greatly improve the service life of the rubber roller.

⑦The machine is equipped with an excellent rubber correction device, which can be used after repeatedly correcting the rubber roller many times.

⑧The phase adjustment of the stencil roller planetary structure, 360 degree operation, stop, both positive and negative operation, the phase adjustment accuracy can reach 0.10mm.

⑨Digital display phase indication makes operation and management easy, intuitive and accurate.

stacker machine

①The paper receiving can be adjusted manually and automatically.

②The paper receiving speed and paper feeding speed can also be adjusted independently.

③The stacking height is 1600 mm.

④The bed platform is lifted by a strong chain.

⑤The paper receiving platform is equipped with an anti-fall device to ensure the safety of the operator.

⑥ The paper receiving board is operated by air pressure. When the paper board is stacked to a certain height, the paper board will automatically extend to support the board.

⑦ Flat wrinkle belt to prevent the cardboard from sliding down.

⑧Adjust the tightness of the paper receiving arm belt independently of the length of the belt.

Transmission gear

①The main transmission gear is made of high-quality steel, carburized and quenched to increase the density, strength, and toughness of the gear material, and is made by grinding teeth.

②Smooth operation, low noise, high hardness, long life, can achieve long-term printing registration.

③The transmission hub adopts a keyless connection ring, which can connect the shaft with the gear, there will be no gap when using large torque, installation and maintenance are more convenient, the machine can have long-term transmission accuracy, and ensure printing registration.

F. Lubrication

1.Each unit adopts an oil pump to achieve oil circulation to achieve circulating spray lubrication.

2. Each oil tank is equipped with an oil storage balancer, which can make the oil level of each group uniform at the same height.

|

Name |

Picture |

place of origin |

|

Bearing |

Human, Harbin |

|

|

Main touch screen |

Weilun |

|

|

PLC |

Tanwan Delta |

|

|

Electrical appliances |

France schneider and chian zhegntai |

|

|

Frequency converter |

Taiwan Delta |

|

|

Relay |

Zhengtai and Delixi |

|

|

Contactor |

China Delixi |

|

|

Main motor |

Hebei “mengniu” |

|

|

ULi rubber pad |

Taiwan chaonai |

|

|

Lead edge feeder wheel |

Taiwan chaonai |

|

|

Slotter kinfe |

Qingdao |

Product detail pictures:

Related Product Guide:

Our commission is to serve our users and clients with best quality and competitive portable digital products for Factory Price For Creasing Cutting Machine - Automatic Printer Die Cutter Machine – Canghai , The product will supply to all over the world, such as: Philadelphia, Marseille, Bangladesh, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our products, please do not hesitate to contact us, we will be happy to provide you with further information!

A good manufacturers, we have cooperated twice, good quality and good service attitude.