Welcome to our websites!

Featured

-

PriceList for 4 Colors Flexo Printing Machine - semi automatic flute laminator machine – Canghai

SPECIFICATION Model CH-1300-A CH-1450-A CH-1550-A CH-1650-A CH-1800-A CH-1900-A (mm) Max size of laminating 1300×1250 1400×1250 1500×1250 1600×1250 1800×1400 1900×1250 Min size of laminating 360×360 360×360 360×360 360×360 360×360 360×360 Economic speed 0-100/min 0-100/min 0-100/min 0-100/min 0-100/min 60pcs/min Laminating precision ±1 ±1 ±1 ±1 ±1 ±1 Power 7KW 7.5KW 7.5KW 7.5KW 7.5KW 7.5KW... -

Manufacturing Companies for Single Facer Paper Corrugation Machine - semi automatic type – Canghai

SPECIFICATION Machine name: Automated Manual Die Cutting Machine Specification MHC-1300B Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard ≥250gsm Corrugated paper: 1-7mm BRIEF INTRODUCE (1)Adopt nodular cast i... -

Newly Arrival China Die Cutting Machine - Automatic Printer Die Cutter Machine – Canghai

The main technical parameters No. 1. Design speed 150piece/min 2. Working speed 100-120pieces/min 3. Max feeding size 1000*2100mm 4. Min feeding size 300*650mm 5. Max printing area 950*2000mm 6. Printing plate thickness 7.2mm 7. Registration precision ±0.5mm 8. Slotter precision ±1.5mm 9. Max depth of slotting 250mm Machine introduction 1. This machine is composed of paper feeding, printing, slotting or die cutting. It can complete the three-layer an... -

Big Discount Corrugated Sheet Stitching Machine - semi automatic type – Canghai

SPECIFICATION Machine name: Automated Manual Die Cutting Machine Specification MHC-1300B Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard ≥250gsm Corrugated paper: 1-7mm BRIEF INTRODUCE (1)Adopt nodular cast i... -

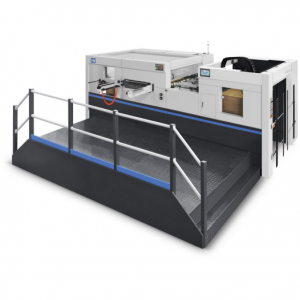

Factory directly supply Semiauto Carton Box Stitching Machine - Automatic Type Corrugated Carton Box Making Machine – Canghai

Specifications Machine name: Automated Manual Die Cutting Machine Specification MHC-1300E Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard≥250gsmCorrugated paper: 1-7mm Brief Introduce The fourth generation of MHC Series Automatic Manual Die Cutting Machine (Tiptronic Die Cutt... -

Fixed Competitive Price Diecutting And Creasing Machine - Stacker Machine For Corrugated Production Line – Canghai

SPECIFICATION ①The paper receiving can be adjusted manually and automatically. ②The paper receiving speed and paper feeding speed can also be adjusted independently. ③The stacking height is 1600 mm. ④The bed platform is lifted by a strong chain. ⑤The paper receiving platform is equipped with an anti-fall device to ensure the safety of the operator. ⑥ The paper receiving board is operated by air pressure. When the paper board is stacked to a certain height, the paper board will automatica... -

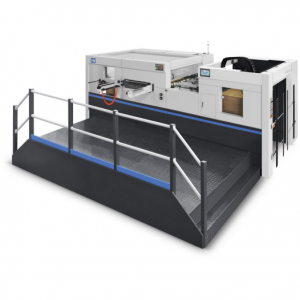

8 Year Exporter Single Facer Plant - Automatic Type Corrugated Carton Box Making Machine – Canghai

Specifications Machine name: Automated Manual Die Cutting Machine Specification MHC-1300E Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard≥250gsmCorrugated paper: 1-7mm Brief Introduce The fourth generation of MHC Series Automatic Manual Die Cutting Machine (Tiptronic Die Cutt... -

Free sample for Flexo Printer Slotter Die Cutter - Stacker Machine For Corrugated Production Line – Canghai

SPECIFICATION ①The paper receiving can be adjusted manually and automatically. ②The paper receiving speed and paper feeding speed can also be adjusted independently. ③The stacking height is 1600 mm. ④The bed platform is lifted by a strong chain. ⑤The paper receiving platform is equipped with an anti-fall device to ensure the safety of the operator. ⑥ The paper receiving board is operated by air pressure. When the paper board is stacked to a certain height, the paper board will automatica... -

Manufacturer for Auto Flute Laminating Machine - semi automatic type – Canghai

SPECIFICATION Machine name: Automated Manual Die Cutting Machine Specification MHC-1300B Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard ≥250gsm Corrugated paper: 1-7mm BRIEF INTRODUCE (1)Adopt nodular cast i... -

OEM Supply Corrugated Cardboard Slitter Scorer - Sheet Cutter Machine For Corrugated Production Line – Canghai

►Structure and Features 1, Cutting length:500mm-9999mm. 2, Cutting precision:±1mm. 3, Uses the independent oil pump and the filter coordinates two groups of copper tubes to distribute in various gears position for the oil,the lubrication and cooling. 4, Helical knife structure,type sawtooth knife,decrease cutting obstruction,low noise. 5, Balance treatment:high quality alloy steel for blade shaft,which helps to keep it good stability. 6, Sun-shape wheels press cardboard in the front and... -

Low price for 2 Color Printer Machine - semi automatic flute laminator machine – Canghai

SPECIFICATION Model CH-1300-A CH-1450-A CH-1550-A CH-1650-A CH-1800-A CH-1900-A (mm) Max size of laminating 1300×1250 1400×1250 1500×1250 1600×1250 1800×1400 1900×1250 Min size of laminating 360×360 360×360 360×360 360×360 360×360 360×360 Economic speed 0-100/min 0-100/min 0-100/min 0-100/min 0-100/min 60pcs/min Laminating precision ±1 ±1 ±1 ±1 ±1 ±1 Power 7KW 7.5KW 7.5KW 7.5KW 7.5KW 7.5KW... -

Factory Cheap Hot Automatic Folder Gluer Stitcher Strapper Machine - Carton Box Stapler Stitching Machine – Canghai

Machine introduction Our factory is a professional one producing DXJ stitch. The DXJ machine is designed according to the advantaged of the same kind of products produced at home and abroad. The machine head is structured by double eccentric gears to work together: the pressure angle adopts installation style which is fit for wire cut and which is exchangeable. All the operation position adopt rolling bearings. Compared to the old machines, the new machines have the following characteris...