Welcome to our websites!

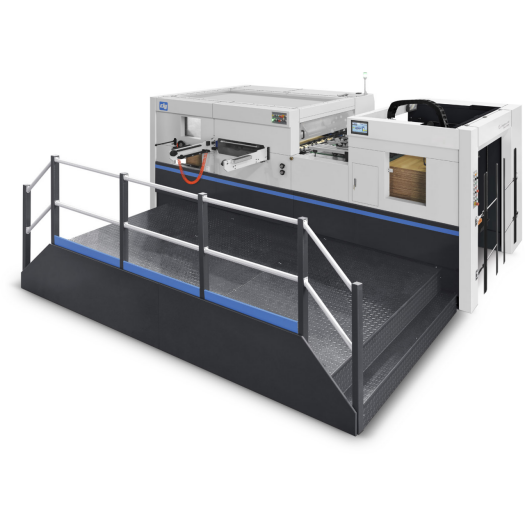

OEM Customized Semi-Auto Corrugated Cardboard Stitching Machine - 3 Ply Corrugated Cardboard Production Line – Canghai

OEM Customized Semi-Auto Corrugated Cardboard Stitching Machine - 3 Ply Corrugated Cardboard Production Line – Canghai Detail:

SPECIFICATION

|

No. |

Name |

Qty |

Feature |

|

1 |

RS Electrical Mill Roll Stand ( with trolley and track) |

3 |

–Toothed chuck,manual discbrakes,pneumatic mechanically actuated lift,panning left and right on the middle–Guide rail length is 4500 mm, the trolley adopt 10 mm plate welding |

|

2 |

PH-60 Pre-heater |

2 |

–The roller φ600 mm,Electric adjustment angle,adjusting heating area within the range of 360 ° |

|

3 |

SF-A12 Single Facer |

1 |

–Corrugated rollerφ320mm, 48CrMo high quality alloy steel,Tungsten Carbide–Independent gearbox,universal joint drive structure–Cylinder control lifting

–Pneumatic control glue,circulating supply glue –Man-machine display |

|

4 |

OB Conveying Bridge |

1 |

–The main beam is connected with the GB 200 channel steel,63 angle steel–Independent frequency motor drive paper conveying–Suction tension and electric correcting |

|

5 |

Triplex Pre-heater |

1 |

–The rollerφ600 mm,electric adjustment angle angle,adjusting heating area within the range of 360 ° |

|

6 |

GM-15 Glue Machine |

1 |

–Glue roller φ269mm,carved 25 line pit type mesh–With preheater device–Independent frequency motor drive

–Circulating supply glue with PLC control –Man-machine interface display |

|

7 |

DF-60 Double Facer |

1 |

–Main frame is 360 mm GB channel steel–Hot plate 600 mm 10pics with plating chrome–4 M cooling section

–Adopt pressure bar lifting by pneumatic control –The upper belt correct automatically –Frequency motor drive |

|

8 |

SS-E Electric Blade Machine |

1 |

–Blade adopt tungsten alloy steel–Electric adjusting and correcting –Automatically grinding–5 blade 8 line |

|

9 |

NC-12 Cut-Off |

1 |

–Full AC servo control–Energy storage type braking–Helical knife structure

–Oil-immersed gear transmission –10.4-inch touch screen display |

|

10 |

LS Sheet Delivery Machine |

1 |

–Electrical adjust the size of cardboard–Cardboard transverse output controlled by pneumatic;–Max stacking height 200mm |

|

11 |

Glue Making System |

1 |

–Customers supply the pipeline–The glue making device includes: carrier tank,main body tank,storage tank,glue feeding pump and returning pump |

|

12 |

Internal Steam System |

1 |

–Steam system components adopt GB valve: Contains rotary joint,up and down distributor ,drain valve and pressure gauge, etc–Boiler and pipeline supply by customer |

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future alongside one another with your esteemed enterprise for OEM Customized Semi-Auto Corrugated Cardboard Stitching Machine - 3 Ply Corrugated Cardboard Production Line – Canghai , The product will supply to all over the world, such as: Nepal, Senegal, Rwanda, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

Write your message here and send it to us