OEM Customized Semi-Auto Corrugated Cardboard Stitching Machine - Double Facer MachineDouble Baker – Canghai

OEM Customized Semi-Auto Corrugated Cardboard Stitching Machine - Double Facer MachineDouble Baker – Canghai Detail:

Machine Description

*Corrugated paper enter into the double facer hot parts with heating and molding after pasted glue, and become board after cooling

Machine Function

*Hot Plates’ surfaces is ground and then chromed plated,width 600mm and 14pcs,cooling parts 4m

*Hot plates adopts the compressed press rollers structure,it lifting adopt pneumatic structure

*Heat conductive pipe of hot plates control the temperature segmented

*The inside of the hot plate is partition isolation structure,making the steam flow in S-shaped direction, and the separation function of steam and water is obvious,then improves the steam usage efficiency

*Up convey belt left and right correct by auto with both sides,Under belt adopt S type manual correct tension device

*Up belt adopt double cylinder S type tension device,down belt manual tension device(small amount adjust)

*Drive rollers’ surface is wrapped by rubber with middle height,to make sure the board output smoothly

*Main drive motor: Variable frequency motor, high force when low speed start, high speed adjusting range, steady to use,easy to mend

*The electrical components adopt international famous brands, working stably and reliable

Machine Technical Parameter

| Working Width |

1800mm |

| Steam Pressure |

0.8-1.3Mpa |

| Air Pressure |

0.6—0.9Mpa |

| Up Drive Roller |

Φ637mm |

| Down Drive Roller |

Φ637mm |

| Front Driven Belt Rroller |

Φ321mm |

| Back Shaping Driven Belt Roller |

Φ215mm |

| Belt Press Roller |

Φ70mm |

| Shaping Holder Roller |

Φ86mm |

|

Note: All the surfaces of the rollers are ground and then chromed plated |

|

Main Components Brand

| Components Name |

Brand |

| Main Frame | Tangshan |

| Cotton Belt |

Shenyang |

| Pneumatic system |

Zhejiang |

| Steam Trap | Henan |

| Main electrical |

Schneider |

| Button |

Schneider |

| Main motor |

Hebei |

| PLC |

Taiwan |

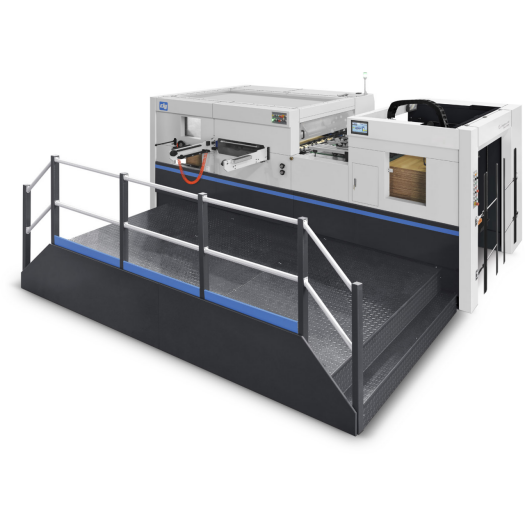

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of OEM Customized Semi-Auto Corrugated Cardboard Stitching Machine - Double Facer MachineDouble Baker – Canghai , The product will supply to all over the world, such as: Juventus, Accra, Tanzania, Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!