Welcome to our websites!

Featured

-

OEM Customized Semi-Auto Corrugated Cardboard Stitching Machine - Double Facer MachineDouble Baker – Canghai

Machine Description *Corrugated paper enter into the double facer hot parts with heating and molding after pasted glue, and become board after cooling Machine Function *Hot Plates’ surfaces is ground and then chromed plated,width 600mm and 14pcs,cooling parts 4m *Hot plates adopts the compressed press rollers structure,it lifting adopt pneumatic structure *Heat conductive pipe of hot plates control the temperature segmented *The inside of the hot plate is partition isolation struct... -

OEM China Three Color Printer Slotter 1270×2500 - Automatic Type Corrugated Carton Box Making Machine – Canghai

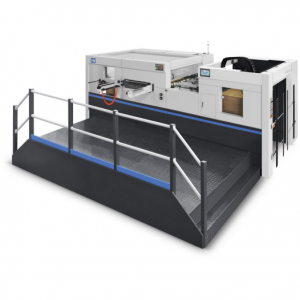

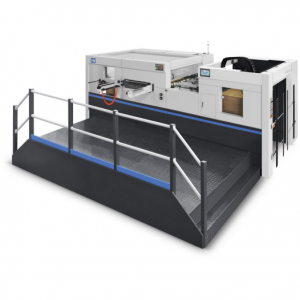

Specifications Machine name: Automated Manual Die Cutting Machine Specification MHC-1300E Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard≥250gsmCorrugated paper: 1-7mm Brief Introduce The fourth generation of MHC Series Automatic Manual Die Cutting Machine (Tiptronic Die Cutt... -

Factory supplied Carton Box Making Machine Price - Automatic Type Corrugated Carton Box Making Machine – Canghai

Specifications Machine name: Automated Manual Die Cutting Machine Specification MHC-1300E Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard≥250gsmCorrugated paper: 1-7mm Brief Introduce The fourth generation of MHC Series Automatic Manual Die Cutting Machine (Tiptronic Die Cutt... -

China Manufacturer for Creasing And Cutting Machine Ml930 - ZYKM High speed printing slotting die cutting machine – Canghai

The thickness of the wallboard is 50mm, and the internal stress of medium frequency quenching and tempering increases the density, hardness, strength, toughness, and conduction performance of the wallboard, artificial aging treatment, large-scale machining center processing in pairs, high strength and high precision. -

Bottom price Printing Slotting Die Cutting - ZYKM High speed printing slotting die cutting machine – Canghai

The thickness of the wallboard is 50mm, and the internal stress of medium frequency quenching and tempering increases the density, hardness, strength, toughness, and conduction performance of the wallboard, artificial aging treatment, large-scale machining center processing in pairs, high strength and high precision. -

Manufacturer of Single Facer Corrugated Carton Machine - semi automatic type – Canghai

SPECIFICATION Machine name: Automated Manual Die Cutting Machine Specification MHC-1300B Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard ≥250gsm Corrugated paper: 1-7mm BRIEF INTRODUCE (1)Adopt nodular cast i... -

OEM/ODM Factory Die-Cutter Machine - Printing Slotting Die-Cutting Machine – Canghai

SPECIFICATION Model 1200×2600 Max.machine speed(Roller Feeder (Pcs/min) 200 Common spending max. 1200*2600 Max. paper skip feeding size (mm) 1600×2600 Min. paper feeding size (mm) 450×630 Max. printing area (mm) 1200×2450 Printing plate thickness (mm) 7.2 Machine wall thickness 65mm Printing accuracy(mm) ±0.5 Slotting accuracy(mm) ±1.5 Print roller diameter(mm) 408 Slot knives width (mm) 7.5mm ... -

100% Original Carton Box Folder Gluer - Two Pieces Corrugated Cardboard Gluer Machine – Canghai

Main institutional performance 1.The feeding unit of the machine has two paper board stack to hold AB two pieces of papers, which helps to improve the production efficiency. Below adopt the air sucking structure, which is conducive to improve transport efficiency and accuracy. 2.Connecting unit adopts hot melt adhesive, four side gauge positioning, ensuring accurate register and high precision. 3.Folding unit adopts manual fold, which resolve the problem of hard to confirm fold place. Th... -

PriceList for Chinese Supplier Paper Mill Roll Stand - semi automatic type – Canghai

SPECIFICATION Machine name: Automated Manual Die Cutting Machine Specification MHC-1300B Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard ≥250gsm Corrugated paper: 1-7mm BRIEF INTRODUCE (1)Adopt nodular cast i... -

Rapid Delivery for 2ply Single Face Machine - semi automatic type – Canghai

SPECIFICATION Machine name: Automated Manual Die Cutting Machine Specification MHC-1300B Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard ≥250gsm Corrugated paper: 1-7mm BRIEF INTRODUCE (1)Adopt nodular cast i... -

Top Suppliers Corrugated Board Printing Machine - semi automatic type – Canghai

SPECIFICATION Machine name: Automated Manual Die Cutting Machine Specification MHC-1300B Maximum paper size: 1300*940mm Minimum paper size: 470 × 420 mm Maximum die cutting size: 1280*920mm Max cutting speed: 5000 sheets/hour Max working pressure: 300 tons Rated power 13.5kw Weight : 18 tons Scope of application Cardboard ≥250gsm Corrugated paper: 1-7mm BRIEF INTRODUCE (1)Adopt nodular cast i... -

Professional China Semi Automatic Stitcher - Carton Box Stapler Stitching Machine – Canghai

Machine introduction Our factory is a professional one producing DXJ stitch. The DXJ machine is designed according to the advantaged of the same kind of products produced at home and abroad. The machine head is structured by double eccentric gears to work together: the pressure angle adopts installation style which is fit for wire cut and which is exchangeable. All the operation position adopt rolling bearings. Compared to the old machines, the new machines have the following characteris...